WIRE ROPE FOR CONSTRUCTION MACHINERY

Products standards

Main standards included: “GB8918 steel wire rope for important purpose”,API 9A specification of steel wire rope ,“YB/T5359 compacted steel wire rope" are normally used,other standard can also be adopted, furthermore we can also design and produce according to customers’ special requirement.

Construction and Characteristics

Main purpose: wire rope for rotary drilling rig, wire rope for crawler crane,wire rope for truck crane, wire rope for tower crane, wire rope for percussion drilling rig.

Properties and Choice of Wire Rope

To choose wire rope, it should be according to the core requirement dependent on the operation conditions of wire rope, at same time consider the basic features of the wire rope and then confirm the specification.Professional technicians from DAWSON GROUP LTD. Possess abundant experience would like to help customers to do this work.

1.Strength

The breaking force given in the standard is the minimum one, only applicable to the new and unused wire rope.The wire rope should not work in a condition where the required force is equal or approaching to the Min. breaking force. The actual breaking force of a new rope must be large or equal to the minimum breaking force, during the effective service life, due to the abrasion on the surface and metal fatigue, the strength of the wire rope may decrease gradually. If not be used appropriately, the strength of the wire rope may vanish suddenly. For the breaking force of the ropes in same size, the rope with larger tensile strength is bigger than the one with lower tensile strength, rope with lWRC is bigger than the one with FC, linear contact lay rope is bigger than point contact lay rope,compacted wire rope is bigger than linear contact rope, double compacted is the biggest one.

2.Anti -fatigue

Anti-fatigue include the metal fatigue of the steel wire in the wire rope, to possess a better performance of anti-fatigue, the steel wire should possess the capability of bending repeatedly under tension.For the same size wire rope, the one which contains more small size steel wire has a better anti-fatigue performance than that which has relative less small size.To reduce the effect of the fatigue, keep it in mind that don't wound the steel wire on the pulley or spool which has a too small diameter.The anti-fatigue performance of 6×36WS class wire rope is better than 6×19 class ones, while 6×19 class is better than 6×7 class.

3.Anti-abrasion ( resistant to metal loss and deformation)

Metal loss means the actual abrasion of the outer steel wire of the wire rope,this abrasion can decrease the tensile force of the steel wire; metal deformation means the shape change of the outer wire of wire rope, the change may decrease the anti-fatigue performance, then affect the move of steel wire when wire rope bends,also this may cause additional stress. For the same size wire rope, the ones which contains less outer steel wire and bigger size outer wire has a better abrasion-resistance than that which contains more outer steel wire and small size outer wire.

The compacted wire rope has relative more steel wires in one strand; it can improve the anti-fatigue performance and the anti-abrasion performance.

The anti-abrasion performance of 6×36WS class wire rope is better than 6×19 class ones, while 6×19class is better than 6×7 class; performance of anti-abrasion of the compacted wire rope is batter than that of ordinary round wire rope.

4.Anti-extrusion

Extrusion is caused by outside pressure on the wire rope, the pressure can cause deformation of the cross section , strand and the core, also can damage the wire rope when it is serious.If the wire rope is damaged by the pressure , the steel wires, strand , core can't move easily when in operation, thus additional stress is produced. Wire ropes with IWRC core have better anti-extrusion performance than the ropes with fiber core; regular lay wire ropes have better extrusion-resistance than lang lay wire ropes. 6 strand wire ropes have better extrusion-resistance than 8 strand and 19 strand wire ropes, compacted wire rope is better than round wire rope , double compacted wire rope has the best performance of anti-extrusion.

5.Stability

This is to describe the maneuverability and the performance.There is no explicit measure method.For example, the wire rope which can be wound and can be paid off on the smooth spool, or there is no twist when being used in a assembly winding system , should be considered as a stable one.The construction of wire rope and construction is important to the stability of wire rope, regular lay wire rope is more stable than lang lay wire rope, wire rope containing 7 wire strands is more stable than these ropes which strands has more steel wires and has more complex construction.

6.Flexibility

Flexibility means the wire rope 's capability of bending to arc.

Small size wire rope bends easily than big size wire rope, wire ropes with fiber core bend easily than the ones with lWRC core , bright wire rope bend easily than galvanized wire rope,point contacting wire rope bends easily than line contacting wire rope, line contacting wire rope bends easily than compacted wire rope.As a universal criterion, for same size wire rope, wire ropes compose by more small size steel wire than these composed by less big size steel wire.

7.Rotation-resistance

Wire ropes tends to rotate around the axis under the load, rotation-resistance means the capability of rotation-resistance When rotation of the clog is forbidden during the lifting operation with wire rope, the rotation-resistant wire rope should be chosen. The rotation-resistance of 35W×7 class wire rope is better that of 18×7 class ones, 18×7 class wire rope is better than compacted 4 strand wire ropes, 4 strand wire ropes is better than 6 strand wire rope.

8.Corrosion-resistance

Corrosion-resistance of galvanized wire rope is better than that of bright wire rope, galvanized steel wire rope with impregnated plastic has best corrosion-resistance.

Use of Wire Rope

storage

The wire rope should be stored in a clean, well-ventilated, dry, dust-free and sheltered place. If it cannot be stored indoors, the wire rope should be covered with waterproof material.

Wire rope should be stored in a place where it is unlikely to be affected by chemical gases, steam or other corrosive agents.

The wire rope is not allowed to have any direct contact with the ground, and a certain space should be left between the lower part of the sheave and the ground to maintain ventilation. It is best to support the wire rope with a bracket placed on the ground that can safely support the entire weight of the wire rope and sheave.

If the wire rope needs to be stored for a long time, especially in a high temperature environment, the drum should be rotated half a circle regularly. Avoid drying out of lubricant. If the ambient temperature exceeds 25°C, perform this operation as many times as possible.

If the wire rope is stored for a long time, the surface scale, dirt or rust should be removed first, and then lubricated. If conditions permit, it should be oiled before installation.

Counting from the date of manufacture, if the steel wire rope has been stored for more than two years, before using the steel wire rope, the rope sample should be sent to the unit with the qualification of steel wire rope testing for steel wire rope testing, and it can be used only after passing the test.

Handling

If the rope roll needs to be moved, the support must be connected to the lifting shaft by a fiber or steel rope to prevent it from falling during the lifting of the rope roll. If it is necessary to install the rope roll on the rope rewinding machine, the rope roll and the bracket must be separated before lifting.

To uncoil, the rope coil must be placed on the rope rewinding machine, so that the rope end can be pulled out from the bottom.

After the rope roll is in place and before the lifting equipment is removed, the rope roll must be prevented from rotating due to weight imbalance. When loosening the outer end of the rope, one must be very careful, beware of its reaction force.

If the rope reversing machine needs to use the braking system, the system should realize the bidirectional braking operation in two opposite directions.

When the rope is unwound, an appropriate tension force shall be provided so as not to introduce additional stress and affect normal use. The tension force shall be at least 2.0% of the minimum breaking force or 10% of the working load (take the two maximum).

Pay off

For wire rope with reel, place the reel on a stand which allows the reel rotate, control the rotation speed of the reel, pull of the wire rope slowly.

For wire rope without reel, pull of the wire rope in the direction reverse to the end of wire rope.

End treatment

Sizing: Iron wire is recommended to be used to seize the wire rope, at the location where the wire rope will be cut, put one end of the iron wire along the wire rope axis, and leave a length of 4 times diameter of wire rope; begin to wind the iron wire on the wire rope closely from the other side of iron wire at the cutting position, the winding length should be about 3 times of rope diameter, then strain the ends of the iron and screw it closely, the screw length should equals the diameter of the wire rope then the screwed section should be set between the groove of the strands.

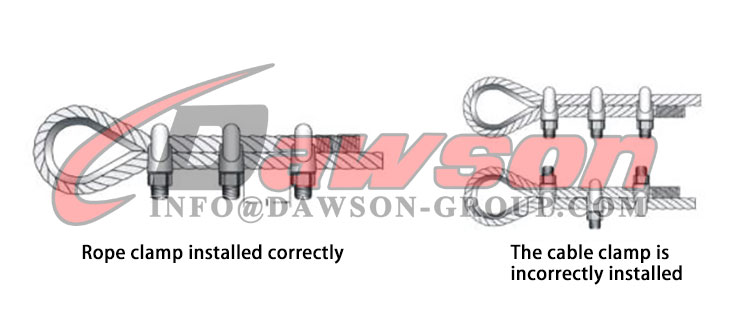

Rope clamp: Steel wire ropes are bended to a ring, fixed with wire,and then using double-saddle bolts clamping.

Fuse end of wire rope: using special electric heating equipment of steel wire rope, under half melting state, through the chunk rotating wire rope and then the rope of all steel wire welding together forming conical end of wire rope.

Pulley drum rope groove inspection

Before installing the new rope, the pulley rope groove must be carefully checked. The surface of the rope groove must be smooth. The radius of the rope groove should be about 7.5% larger than the nominal radius of the steel wire rope, but not less than 5%. Use the matching special radius gauge to measure the rope groove radius, as follows:

The minimum diameter of the new rope groove Ømin=1.05d

The maximum diameter of the new rope groove Ømax=1.10d

Recommended diameter of new rope groove Ø=1.08d

Among them: d: nominal diameter of steel wire rope (mm)

g=rope groove diameter=1.08d

h= 1.75d

hmin.= 1.41

d = 45° ~60°

The actual diameter of the wire rope is absolutely not allowed to be greater than the center distance of the rope groove of the drum. The relationship between the nominal diameter of the wire rope and the center distance of the rope groove of the drum is as follows:

Among them: d= nominal diameter of steel wire rope (mm)

p=Rope groove center distance (mm)

p=1.15xd steel wire rope with a maximum diameter of 10mm

p=1.12×d steel wire rope with a maximum diameter of 20mm

p=1.11×d Steel wire ropes with a diameter exceeding 20mm

h= 0.4×d

r=0.55x d

When wind the rope on the drum in multi-layers, must coil the bottom wire rope closely under tension.otherwise the wire ropes in upper layer will wedge into the lower layer and cause damage by extrusion.After the wire rope is installed, it should be run for some time under medium load with a low speed.After the wire rope adapt to the application conditions, then gradually increase the operation speed and increase the loading. Forbid to use the wire rope under heavy load in high speed as soon as it is installed.

Note:the new and unused wire rope is more likely to be extruded than the used wire rope.

Eccentricity check

Before installing the new rope, the eccentric angle must be checked and measured. The eccentric angle refers to the angle between the center line of the steel wire rope and the vertical line of the pulley axis when the steel wire rope is wound to the edge of the drum, whether it is a Lebus "fence" drum It is still a smooth reel. In any case, the inclination angle of the rotating wire rope shall not be greater than 1:15 (4.0°), and in the main working part, even an inclination angle of 1° will have an adverse effect on the rope. For semi-rotation-resistant And non-rotating wire rope, the inclination must not exceed 1:40 (1.5°).

Eccentric angle

Sheave Centerline

Drum axis

Correct rope eccentric angle

Install

When installing new ropes, the same type of wire rope as originally installed should be used as a replacement wire rope. If different, it shall be ensured that it has at least the same characteristics as the rope it replaces.

It is recommended to discard the old wire ropes before installing new ones during installation. If the old rope is used to pull the new rope, the ends of the new rope and the old rope are connected with a small diameter steel wire rope to avoid the transfer of rotation from the old rope to the new rope.

When the steel wire rope is wound in multiple layers on the drum, the bottom steel wire rope must be wound tightly under load, otherwise the upper layer steel wire rope is easily wedged into the lower layer steel wire rope to form a crushing injury.

After the new steel wire rope is installed, it should be operated under low-speed and medium-load conditions for a period of time. After the steel wire rope adapts to the use state, the running speed of the steel wire rope will be gradually increased to increase the lifting load. Do not use it under high-speed and heavy load immediately after installation. .

NOTE: New, unused wire rope is more likely to be pinched than used wire rope.

Check and Replacement of Wire Rope

Frequency and item of checking

APIRP54 suggest, inspect all the lifting rope being used visually everyday, and perform a thorough examination every month and make a monthly examination record.

Following should be inspected periodically: diameter of wire rope, lay pitch, numbers of broken wires,surface damage of wire rope.

Type of broken wire

Wire breaking is one of the signs of deterioration of wire rope.According to the location of the broken wire in wire rope, it can be classified into 2 types; one is broken wire in the crown of strand and broken wires in the dent location between strands.The broken wires in the running rope is the wires in the crown of strands, locates in the abrasion position of wire rope surface. Broken wires in standing rope often take place in the dent between strands, present at the fixed ends or other location where the rope is restricted,steel wires in such location are damaged by the energy released by damping vibration .

How to find out broken wires

Remove the wire rope from the pulley and put it at plain and steady position, clean the surface of the wire rope,thus can find the breaks in the crown of strands.

Bend the wire rope, can expose the breaks hiding in the dents between strands.Breaks in the wire rope need to be examined more carefully then it can be found.

Location of examination

·Drum

When the wire rope is coiled on the drum, it may rub with the rope of upper lays at the overlap point,thus the edge of the wire rope will be rubbed and damaged.When wire rope fall into the dent between the 2 sections ropes,then frictions happen. Also when there is a fleet between adjacent wire ropes, then friction may take place.when wire rope traverse the upper layer, for there is only one contacting point, so it is easy to be extrude.This extrusion may increase the pressure, and this pressure may deform the cross section of wire ropes,strands and core, thus damage the wire rope.Extrusion may happen at the exchange point of the layer, and the out edge of the drum where the wire rope wedge in.New wire rope is easily to be extruded and dam aged, if the wire rope in former 2 layers or 3 layers is not tensed, then outer wire rope may wedge into the inner layer and can cause serious damage.Compared with grooved drum,when single layer wire rope is coiled in plain drum, the wire rope and drum will be worn more quickly.

·Pulley

Wire rope groove will become less and less during the application, the groove which is too small may hoop and shrink wire rope, increase the abrasion, also it will restrict the slide of the strand and steel wire thus cause additional stress; a groove which is too big may stave the wire rope.Above 2 statuses can decrease the service life of wire rope.

·End accessories

Movement of wire rope near to the end accessories is limited, when the damping vibration happen on one section of the wire rope, then this section will be fatigued.

·Contact point

The contact point is to hoist to in each ascending initial load, steel wire rope and drum or pulley contact area. These areas will soon appear internal and external wear for two reasons: one is the steel wire rope runtime acceleration greater load; The second is rope will load the diameter in transfer to block or on the web. In the point of contact areas that need to be key observation wire diameter decreases,broken wire, steel wire rope wear and deformation.

Replacement of wire rope

·Running rope

For 6 stand and 8 strand wire rope, if find 6 broken steel wires distributed randomly in one lay pitch, or in one strand find 3 broken steel wires, then replace the wire rope.

For rotation-resistant wire rope, find 2 broken steel wires distributed randomly within the length of 6times diameter of wire rope, or find 4 broken steel wires within 30 times of diameter of wire rope,and then replace the wire rope.

Standing rope (guy line,life line, hang line)

In one lay pitch find 3 broken steel wires,or at the end find more than one broken wires, or find broken wire in the dent between strands, then replace the wire rope.

Replace the wire rope in other necessary conditions

·Corrosion cause wire rope sunken

·Find corroded steel wire in the end joints

·End joints was corroded, damaged, bent or worn or be used in wrong manners There is kink , extrusion, cut or wire knot or stretched core

·1/3 the worn location is over than the 1/3 of the original diameter of the wire rope

·The diameter of wire rope decrease greatly ,There is evidence show that the wire rope is stroke

and dam aged

·The lay pitch increase obviously

Research on Compaction Technology

The company introduces foreign advanced compacted strand tooling technology, and obtains compacted strand steel wire rope with excellent performance through online pressing.

√Higher breaking force - increase the contact area between adjacent steel wires of the strands, further increase the cross-sectional area of the strands, thereby increasing the breaking force of the wire rope, with a higher safety factor

√Good wear resistance - the compacted strand steel wire rope has a larger contact area with the matching wheel groove during use, which not only prolongs the service life of the wheel groove, but also makes the wire rope show good wear resistance

√Excellent impact load resistance - the metal density of the strands increases, making it more difficult for the steel wires to slide relative to each other. After the twisted strands are compacted, the rigidity increases, which increases the impact load capacity of the steel wire rope while improving the stability of the strand structure

√More suitable for multi-layer winding system - the use of compacted strand steel wire rope can prevent the early structural breakage of the steel wire rope in the multi-layer winding of the drum, and is suitable for multi-layer winding drums in marine engineering. The surface of the drum can be smooth or with rope groove (Lebus "Ribas")

Research on Overmolding Technology

The outer surface of the steel wire rope and the contact part between the steel core and the outer layer strands are covered with injection molding resin materials, which can form a buffer layer between strands or between strands and steel cores to reduce mutual extrusion stress, and the outer layer is coated The resin inside can seal and protect the grease inside the wire rope, forming a composite wire rope.

√Excellent wear resistance - prevent the direct friction between the steel wire and the pulley, and reduce the internal friction of the steel wire

√Excellent fatigue resistance——eliminate stress concentration of steel wires and improve structural stability √Excellent impact resistance——to achieve buffering effect and improve the impact resistance of steel wire ropes √Sufficient internal lubrication—to seal and store grease

√Good anti-corrosion effect - better weather resistance, water resistance, sea water resistance, and good corrosion resistance to alkali, acid, oil, etc.

√Excellent pressure resistance - the presence of coating injection resin can reduce the rewinding performance of multi-layer winding drums and the internal extrusion force of steel wire ropes

The surface does not need to be smeared with grease, it has a beautiful appearance, and is not easy to be contaminated with dust and impurities. It is more suitable for use in a production environment that is afraid of being polluted by oil and dust; the coating injection resin can be selected in any color, and can be customized according to user needs.

Grease Technology Research

Cooperate with well-known domestic lubricating oil research institutes to jointly develop high-adhesive marine special oils Ⅰ and Ⅱ for marine anchor cables

Type Ⅰ (dark brown uniform ointment)

√Traditional wire rope grease is suitable for various offshore working conditions

√Good adhesion

√ Better corrosion protection √ Better lubrication

Type Ⅱ (dark green uniform ointment)

√ Better high and low temperature stability, operating temperature -30-90°C, suitable for more challenging offshore operating environments

√ Better adhesion, forming a firm protective film

√Better anti-salt spray performance, to meet the use of steel wire rope in high salt spray environment

√Better resistance to heat and humidity, to meet the use of steel wire ropes in high humidity environments

The Main production equipment

The Main testing equipment:

Wire Rope Breaking Testing Machine:

External service inspection

Non-destructive testing - NDT

Non-destructive testing technology for steel wire rope. Non-destructive testing-NDT detection method, which integrates 4C technologies such as computer, communication, display and control, realizes interconnection in the system with networked communication as a link, solves the problem of real-time non-destructive flaw detection of steel wire ropes in service in an all-round way, and enables users to operate during equipment operation. At the same time, retrieve the real-time flaw detection status of the wire rope at any time to understand and control the safety status of the wire rope.

Online lubrication maintenance

Online automatic lubrication technology for steel wire rope. When the steel wire rope passes through the device, the impurities attached to its surface will be scraped off by the rubber seal in the lubricator chamber, and at the same time, the lubricant injected into the lubricator chamber will be evenly spread under the pressure exerted by the oil injection pump on the surface of the wire rope.

Cast in Place

Application of Wire Rope for Oceanography:

Steel Wire Rope Catalogue Download:

Factory & Package Show:

English

English