Φ20-Φ210 Dock Steel Tie Rod Type I, Steel Tie Rod Connection, Marine Tie Rods

- Dawson Group Ltd. - China Manufacturer, Supplier, Factory

steel tie rod

Introduction to steel tie rods

The steel tie rod is composed of a steel rod body and connecting parts, and mainly bears the axial static load tension. Steel tie rods can be formed into a variety of structural forms through connectors of different structures. They can be matched with a variety of structures and are flexible and simple to install. With a tensioner, not only can the length of the steel tie rods be adjusted, but also prestressing can be easily applied, giving the structure greater strength. Stiffness. Widely used in roof supports, column supports, cable-stayed supports, hanging structures, and under trusses in various structures.

Chords and tower column ground anchors, bridge main cable anchors, etc.

The rod body is usually made of high-quality alloy structural steel. It achieves excellent mechanical properties after overall quenching and tempering treatment. It has the advantages of high strength and good toughness. At the same time, the steel tie rod is easy to be treated with fire protection and anti-corrosion. After special processing, it can meet the fatigue test of 2 million times. requirements.

Construction bridge steel tie rods

●Different connectors and rods can achieve a variety of connection forms. At the same time, Dawson Rigging has strong research and development capabilities.

●More connection structures can be provided according to user needs.

●Steel tie rods can use sensing connectors or sensing pins to realize real-time stress monitoring of steel tie rods.

Shipyard steel tie rod

The steel tie rods of the shipyard and wharf adopt forging one-piece forming technology as a whole to enhance the bending resistance of the threaded parts of the rod body. After the overall quenching and tempering treatment, the comprehensive performance is improved.

According to the different structures of sheet pile walls and anchor walls of shipyards and wharfs, the steel tie rods of shipyards and wharfs have a variety of end connection structures to meet the connection with various structures. One-way hinge, two-way hinge or universal hinge structure can be used in the middle of the steel tie rod to reduce the bending moment caused by ground settlement on the steel tie rod. In fact,

In application, a variety of structures can be combined to meet more complex terrains. The tensioner of the dock steel tie rod can adjust the length of the steel tie rod and can also be used to tension the steel tie rod.

The steel tie rods of shipyards and wharfs need to be treated with anti-corrosion as a whole after installation and tensioning. Our company can recommend anti-corrosion solutions according to different application environments of steel tie rods.

Structural diagram of end connection of steel tie rods at shipyard and wharf

Steel tie rods connected to Z-shaped steel sheet piles

(Ordinary backing plate, spherical nut + spherical backing plate structure)

Steel tie rods connected to U-shaped steel sheet piles

(Spherical nut + spherical pad structure)

Steel tie rod and steel pipe pile connection

Steel tie rod and steel pipe pile connection 2

Steel tie rod connected to concrete wall

Steel tie rods connected to H-shaped steel sheet piles

High strength anchor

High-strength anchors usually use high-quality alloy structural steel, which achieves excellent mechanical properties after overall quenching and tempering treatment. It has the advantages of high strength and good toughness, and is easy to undergo anti-corrosion treatment. Mainly used in tower anchors of suspension bridges and cable-stayed bridges, and anchorage positions of bridge main cables

High strength anchor

Anchor type suspension bridge anchoring system

Introduction to steel tie rod body technology

Steel tie rods can be divided into two types: equal-strength forged structures and non-equal-strength structures according to the processing technology of the rod body. The equal-strength forged structure is Dawson Rigging's patented technology. After the rod body is forged, the bearing capacity of the thread is increased. The bearing capacity of the rod body with the same diameter is 15% higher than that of the non-equal-strength structure rod body.

Equally strong forged structure

non-equal strength structure

Dock steel tie rod type I dimension table Φ20-Φ210

Rod diameter D

(mm) | L

(mm) | A

(mm) |

| 20 | 65 | M24×3 |

| 25 | 75 | M30×3.5 |

| 30 | 85 | M36×4 |

| 35 | 100 | M42×4.5 |

| 40 | 105 | M48×5 |

| 45 | 105 | M56×5.5 |

| 50 | 125 | M60×5.5 |

| 55 | 140 | M68×6 |

| 60 | 145 | M72×6 |

| 65 | 165 | M76×6 |

| 70 | 170 | M85×6 |

| 75 | 190 | M90×6 |

| 80 | 210 | M95×6 |

| 85 | 230 | M100×6 |

| 90 | 250 | M105×6 |

| 95 | 270 | M110×6 |

| 100 | 285 | M115×6 |

| 105 | 290 | Tr125×10 |

| 110 | 300 | Tr130×10 |

| 115 | 310 | Tr135×10 |

| 120 | 320 | Tr140×10 |

| 125 | 325 | Tr150×12 |

| 130 | 330 | Tr155×12 |

| 135 | 335 | Tr160×12 |

| 140 | 340 | Tr165×12 |

| 145 | 345 | Tr170×14 |

| 150 | 350 | Tr175×14 |

| 155 | 355 | Tr180×14 |

| 160 | 360 | Tr185×14 |

| 165 | 365 | Tr195×16 |

| 170 | 370 | Tr200×16 |

| 175 | 375 | Tr205×16 |

| 180 | 380 | Tr210×16 |

| 185 | 385 | Tr220×18 |

| 190 | 390 | Tr225×18 |

| 195 | 395 | Tr230×18 |

| 200 | 400 | Tr235×18 |

| 205 | 405 | Tr240×18 |

| 210 | 410 | Tr245×18

|

Products Show:

Other Related Products:

Mechanical properties and parameters of steel tie rod products (GB/T 20934-2016)

Mechanical properties of steel tie rods for buildings, bridges and wharfs (alloy steel material)

Note 1: When the yield is not obvious, Rp0.2 can be measured instead of the upper yield strength;

Note 2: If there are higher requirements for -40°C and -60°C impact absorption energy, they will be stipulated by agreement between the supplier and the buyer;

Note 3: The length of the furnace test rod is 400mm, and the middle 200mm is taken when measuring the mechanical properties.

| Strength level | Quality level | Rod diameter D

mm | Yield strength ReH/Rp 0.2MPa | Tensile strength

Rm

MPa | Elongation after break A% | Reduction of area % | Impact absorbed energy KV2 |

| J | Temperature/℃ |

| not less than |

| DS-GLG 345 | I | 20~210 | 345 | 470 | 22 | 50 | 34 | 0 |

| II | 34 | -20 |

| Ⅲ | 27 | -40 |

| Ⅳ | 27 | -60 |

| DS-GLG 460 | I | 20~210 | 460 | 610 | 20 | 50 | 34 | 0 |

| II | 34 | -20 |

| Ⅲ | 27 | -40 |

| Ⅳ | 27 | -60 |

| DS-GLG 550 | I | 20~210 | 550 | 750 | 18 | 50 | 34 | 0 |

| II | 34 | -20 |

| Ⅲ | 27 | -40 |

| Ⅳ | 27 | -60 |

| DS-GLG 650 | I | 20~210 | 650 | 850 | 15 | 45 | 34 | 0 |

| II | 34 | -20 |

| Ⅲ | 27 | -40 |

| Ⅳ | 27 | -60

|

Theoretical yield load table of equal strength alloy steel tie rods

| Rod body nominal diameter | Strength grade (N/mm) |

| DS-GLG 345 | DS-GLG 460 | DS-GLG 550 | DS-GLG 650 |

| Theoretical yield load ≥ (KN) |

| 20 | 108 | 144 | 173 | 204 |

| 25 | 169 | 226 | 270 | 319 |

| 30 | 244 | 325 | 389 | 459 |

| 35 | 332 | 442 | 529 | 625 |

| 40 | 433 | 578 | 691 | 816 |

| 45 | 548 | 731 | 874 | 1033 |

| 50 | 677 | 903 | 1079 | 1276 |

| 55 | 819 | 1092 | 1306 | 1544 |

| 60 | 975 | 1300 | 1554 | 1837 |

| 65 | 1144 | 1526 | 1824 | 2156 |

| 70 | 1327 | 1769 | 2116 | 2500 |

| 75 | 1523 | 2031 | 2429 | 2870 |

| 80 | 1733 | 2311 | 2763 | 3266 |

| 85 | 1957 | 2609 | 3119 | 3687 |

| 90 | 2194 | 2925 | 3497 | 4133 |

| 95 | 2444 | 3259 | 3897 | 4605 |

| 100 | 2708 | 3611 | 4318 | 5103 |

| 105 | 2986 | 3981 | 4760 | 5626 |

| 110 | 3277 | 4369 | 5224 | 6174 |

| 115 | 3582 | 4776 | 5710 | 6748 |

| 120 | 3900 | 5200 | 6217 | 7348 |

| 125 | 4232 | 5642 | 6746 | 7973 |

| 130 | 4577 | 6103 | 7297 | 8623 |

| 135 | 4936 | 6581 | 7869 | 9299 |

| 140 | 5308 | 7078 | 8462 | 10001 |

| 145 | 5694 | 7592 | 9078 | 10728 |

| 150 | 6094 | 8125 | 9714 | 11481 |

| 155 | 6507 | 8675 | 10373 | 12259 |

| 160 | 6933 | 9244 | 11053 | 13062 |

| 165 | 7373 | 9831 | 11754 | 13892 |

| 170 | 7827 | 10436 | 12478 | 14746 |

| 175 | 8294 | 11059 | 13222 | 15626 |

| 180 | 8775 | 11700 | 13989 | 16532 |

| 185 | 9269 | 12359 | 14777 | 17463 |

| 190 | 9777 | 13036 | 15586 | 18420 |

| 195 | 10298 | 13731 | 16417 | 19402 |

| 200 | 10833 | 14444 | 17270 | 20410 |

| 205 | 11381 | 15175 | 18144 | 21443 |

| 210 | 11943 | 15925 | 19040 | 22502

|

Theoretical yield load table of non-equal strength alloy steel tie rods

| Rod diameter (mm) | Strength level (N/mm²) |

| DS-GLG 345 | DS-GLG 460 | DS-GLG 550 | DS-GLG 650 |

| Theoretical yield load ≥ (KN) |

| 20 | 84 | 113 | 135 | 159 |

| 25 | 122 | 162 | 194 | 229 |

| 30 | 193 | 258 | 308 | 364 |

| 35 | 239 | 319 | 381 | 451 |

| 40 | 336 | 449 | 536 | 634 |

| 45 | 450 | 600 | 718 | 848 |

| 50 | 508 | 677 | 810 | 957 |

| 55 | 606 | 808 | 966 | 1142 |

| 60 | 700 | 933 | 1116 | 1319 |

| 65 | 923 | 1230 | 1471 | 1738 |

| 70 | 1054 | 1405 | 1680 | 1935 |

| 75 | 1193 | 1591 | 1902 | 2248 |

| 80 | 1341 | 1788 | 2138 | 2527 |

| 85 | 1498 | 1997 | 2388 | 2822 |

| 90 | 1706 | 2275 | 2720 | 3214 |

| 95 | 1928 | 2570 | 3073 | 3632 |

| 100 | 2163 | 2884 | 3448 | 4075 |

| 105 | 2412 | 3216 | 3845 | 4544 |

| 110 | 2674 | 3566 | 4263 | 5038 |

| 115 | 2950 | 3934 | 4703 | 5558 |

| 120 | 3240 | 4319 | 5165 | 6104 |

| 125 | 3314 | 4419 | 5283 | 6244 |

| 130 | 3620 | 4827 | 5771 | 6821 |

| 135 | 3940 | 5154 | 6281 | 7423 |

| 140 | 4274 | 6598 | 6813 | 8052 |

| 145 | 4621 | 6161 | 7366 | 8705 |

| 150 | 4844 | 6459 | 7723 | 9127 |

| 155 | 5213 | 5951 | 8311 | 9822 |

| 160 | 5596 | 7461 | 8921 | 10543 |

| 165 | 5992 | 7989 | 9552 | 11289 |

| 170 | 6401 | 8535 | 10205 | 12060 |

| 175 | 6664 | 8885 | 10624 | 12556 |

| 180 | 7096 | 9461 | 11312 | 13369 |

| 185 | 7541 | 10054 | 12022 | 14208 |

| 190 | 8000 | 10666 | 12753 | 15072 |

| 195 | 8293 | 11057 | 13220 | 15624 |

| 200 | 8774 | 11698 | 13987 | 16530 |

| 205 | 9268 | 12357 | 14775 | 17461 |

| 210 | 9776 | 13034 | 15584 | 18418

|

Steel tie rod installation instructions

01

Install required tools

a) Steel rod or special wrench; (according to the required size) b) Skids, chain hoist or other lifting tools;

c) Special tensioning tooling and hydraulic jack or torque wrench; (according to required tonnage) d) Testing tools. (As required by the project)

02

Check before installation

a) Whether the quantity, length and number of steel tie rods are consistent with the order contract;

b) Whether the steel tie rod accessories are complete, whether the surface coating is intact, and whether the threaded part is rusty.

c) Check whether the steel tie rod is deformed or damaged.

03

Precautions before installation

a) Read this instruction manual carefully. b) Draw up a detailed installation plan.

c) Before installation, correspond to the goods in the installation list (including length, specifications, form, quantity, etc.) to ensure that the installation is correct.

d) During the installation and lifting process, it is necessary to lift it gently to prevent the tie rod and its accessories from colliding and scratching the paint layer on the surface. If any scratches or peeling paint are found on the surface, the paint should be repainted in time.

e) During the installation process, prevent sand and other debris from sticking to the threaded parts of the tie rod and tensioner.

f) It is strictly forbidden to drag the steel tie rod on the ground to prevent damage to the paint layer and labels.

g) The threaded parts of the tie rods, tensioners and nuts are coated with an appropriate amount of anti-rust oil before leaving the factory. In order to prevent the anti-rust oil from hardening over time, do not open the package before installation.

h) The unpacked tie rods and tensioners should be placed on skids and not directly on the ground to prevent the anti-rust oil on the threads from adhering to sand and affecting installation.

04

Construction steel tie rod installation

a) Open the package, install the parts except the pin and end cover in sequence on the ground, and adjust the tensioner to the appropriate position. During installation, pay attention to the direction of thread rotation to prevent damage to the threads and avoid debris sticking to the threads. (According to contract requirements, shorter length tie rods can be assembled before leaving the factory and shipped)

b) Measure the length between the steel tie rod installation nodes and determine the initial installation length of the steel tie rod. (Make sure the O-shaped or U-shaped joints and tensioners maintain a safe screwing length, usually 8-10 buckles).

c) Lift the assembled tie rod to the corresponding installation position, insert the pin, and tighten the end cover. When the length of the tie rod is large, use a crane to lift it, and use soft slings to prevent scratching the anti-corrosion layer on the surface of the tie rod.

d) When the tensioning tonnage is large, special tensioning equipment needs to be installed on the two long sheaths. The special tensioning tool can keep the tensioner in a non-stressed state. When the predetermined force value is reached, use a wrench to tighten the tensioner to achieve the purpose of tensioning. e) For steel tie rods without a tensioner in the middle, special tensioning equipment can be installed on the joints or steel structures at both ends. The special tensioning tool can keep the middle rod in a non-stressed state. After reaching the predetermined force value, tighten the rod with a wrench.

f) Remove the tensioning tooling and complete the installation.

g) When the tension is small, a torque wrench can be used to tighten; when there is no tension requirement, a wrench can be used to tighten the tie rod directly. h) After all installation is completed, anti-corrosion and other surface treatments will be carried out on the whole.

05

Shipyard Steel Tie Rod Installation

a) Insert the embedded rods at both ends into the anchor wall or steel sheet pile, taking care to prevent the threads from being damaged and sand from sticking to the threads. When installing the backing plate, nuts and locking nuts, the external threads of the tie rods must be properly exposed. Usually about 5-6 buckles. The installation status is shown in Figure 1:

b) Install the connecting plate, pin, cotter pin and intermediate rod in sequence. The cotter pin should have a larger opening to prevent the cotter pin from loosening. During installation, ensure that the tie rod remains approximately horizontal, and spacers can be placed lower in the one-way structure composed of two connecting plates. Note that the threads of the two long rods are in opposite directions to prevent damage to the threads and sand from sticking to the threads.

The incorrect installation status is shown in Figure 2, and the correct installation status is shown in Figure 3.

c) Install the intermediate tensioner. Use a suitable steel rod or special wrench to insert into the mounting hole in the middle of the tensioner and rotate the tensioner to tighten the threads at both ends. Note that the number of screws must be reached. By adjusting the tensioner, the tension of the tie rod is appropriate, and the nuts at both ends can also be adjusted. Pay attention to the direction of rotation of the internal thread when installing.

d) After the above installation work is completed, perform tensioning. Install a special tensioning tool and a hydraulic jack on one end of the tie rod. After starting the jack to tension to the specified tonnage, tighten the nuts and locking nuts. Figure 4 shows a simple tensioning diagram:

e) Remove the tooling and jack and complete the installation.

f) After all installation is completed, the installation unit will perform anti-corrosion treatment as a whole.

06

Trouble analysis and troubleshooting

07

transportation and storage

a) After the goods are transported to the designated location, they should be stored in a ventilated place to prevent chemical corrosion and moisture. If stored outdoors, it should be stored in a dry place on the ground, padded with sleepers, and covered with a rainproof cloth.

b) Oil-filled spreaders and slings should not be used when transporting steel tie rods and parts.

c) Avoid bumping and missing components during storage and transportation, and ensure that parts labels are intact.

d) Products should be firmly padded, clamped, and fixed in the packaging box to prevent the goods from moving or shifting during handling or transportation. When hoisting the product (especially the pole body), it should be hoisted with two legs using slings. The bundling form is shown in Figure 5.

e) The pull rod is strictly prohibited from being dragged on the ground or soaked in water.

f) When transporting and stacking the tie rods after storage, each layer should be stacked neatly as shown in Figure 6, and pads should be used between each layer to prevent damage to the threads and facilitate lifting.

g) The product is strictly prohibited from colliding with obstacles during lifting as shown in Figure 7, especially the threaded end is strictly prohibited from colliding with obstacles.

08

maintenance

a) Steel tie rods are generally coated with epoxy zinc-rich primer before leaving the factory. The protection time is short (about one month). They should be installed as soon as possible and undergo secondary anti-corrosion treatment. If the primer is damaged, it should be repaired in time. At the same time, when performing secondary anti-corrosion treatment, please eliminate dust and oil on the surface of the steel tie rod.

b) Steel tie rods are often exposed to direct sunlight and are used outdoors and are more likely to come into contact with corrosive chemicals such as water, acid, alkali, salt, etc. The paint surface of the steel tie rods should be inspected and it is found that the paint surface is aging, deteriorating, peeling, and blistering. The damaged area should be polished in time until the base material is exposed and repainted. If there is a fire retardant coating layer, the fire retardant coating should be recoated in time.

c) Each part of the steel tie rod is generally connected through threads. When the steel tie rod is exposed to external factors, it will vibrate for a long time, and the threads will cause abnormal loosening and withdrawal problems. Therefore, the threaded connection part must be maintained more intensively. If the screws between the pin and the end cover are loose, the pin will move or even fall off. At the same time, pay attention to the loose sheath and check and tighten it regularly.

d) Avoid hammering and hammering the steel tie rods during installation and rough operations, and avoid artificial hammering and hammering of the steel tie rods during use.

e) Steel tie rods are used in severe northern winters. Ice accumulation on the surface of steel tie rods must be cleaned in time to prevent low-temperature damage.

f) If steel tie rods are deformed or damaged by external forces, they should be handled by a team with professional construction qualifications and replaced in time.

| Fault phenomenon | Analyze the reasons | Method of exclusion |

| Difficulty threading | Collision and deformation of screw threads | Trim with a triangular file |

| Sand on the threads | Clean or wipe threads |

| Rusty threads | Use a triangular file or steel brush to remove rust |

| Tensioner cannot be installed | Wrong thread direction or tooth profile deviation | Replace tensioner or tie rod

|

07

transportation and storage

a) After the goods are transported to the designated location, they should be stored in a ventilated place to prevent chemical corrosion and moisture. If stored outdoors, it should be stored in a dry place on the ground, padded with sleepers, and covered with a rainproof cloth.

b) Oil-filled spreaders and slings should not be used when transporting steel tie rods and parts.

c) Avoid bumping and missing components during storage and transportation, and ensure that parts labels are intact.

d) Products should be firmly padded, clamped, and fixed in the packaging box to prevent the goods from moving or shifting during handling or transportation. When hoisting the product (especially the pole body), it should be hoisted with two legs using slings. The bundling form is shown in Figure 5.

e) The pull rod is strictly prohibited from being dragged on the ground or soaked in water.

f) When transporting and stacking the tie rods after storage, each layer should be stacked neatly as shown in Figure 6, and pads should be used between each layer to prevent damage to the threads and facilitate lifting.

g) The product is strictly prohibited from colliding with obstacles during lifting as shown in Figure 7, especially the threaded end is strictly prohibited from colliding with obstacles.

08

maintenance

a) Steel tie rods are generally coated with epoxy zinc-rich primer before leaving the factory. The protection time is short (about one month). They should be installed as soon as possible and undergo secondary anti-corrosion treatment. If the primer is damaged, it should be repaired in time. At the same time, when performing secondary anti-corrosion treatment, please eliminate dust and oil on the surface of the steel tie rod.

b) Steel tie rods are often exposed to direct sunlight and are used outdoors and are more likely to come into contact with corrosive chemicals such as water, acid, alkali, salt, etc. The paint surface of the steel tie rods should be inspected and it is found that the paint surface is aging, deteriorating, peeling, and blistering. The damaged area should be polished in time until the base material is exposed and repainted. If there is a fire retardant coating layer, the fire retardant coating should be recoated in time.

c) Each part of the steel tie rod is generally connected through threads. When the steel tie rod is exposed to external factors, it will vibrate for a long time, and the threads will cause abnormal loosening and withdrawal problems. Therefore, the threaded connection part must be maintained more intensively. If the screws between the pin and the end cover are loose, the pin will move or even fall off. At the same time, pay attention to the loose sheath and check and tighten it regularly.

d) Avoid hammering and hammering the steel tie rods during installation and rough operations, and avoid artificial hammering and hammering of the steel tie rods during use.

e) Steel tie rods are used in severe northern winters. Ice accumulation on the surface of steel tie rods must be cleaned in time to prevent low-temperature damage.

f) If steel tie rods are deformed or damaged by external forces, they should be handled by a team with professional construction qualifications and replaced in time.

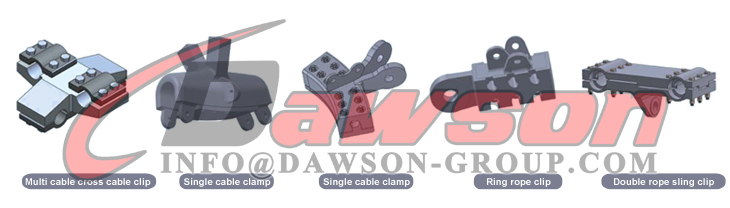

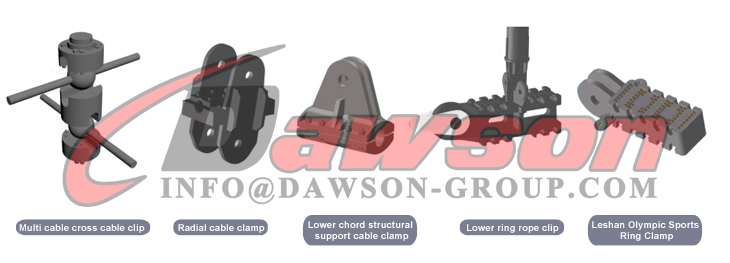

Cable Fittings:

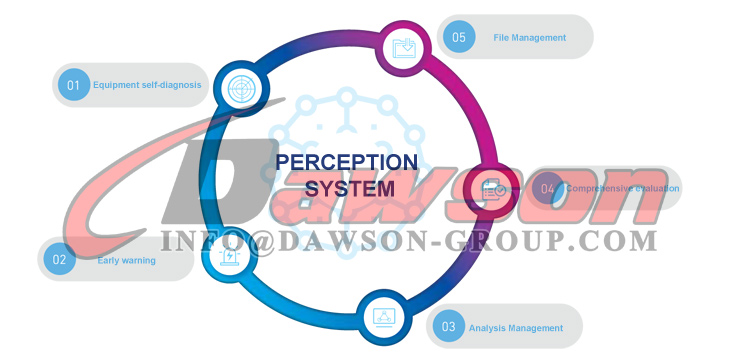

Health Monitoring

System Structure

Description of main features of the system

01 System measurement accuracy: 1.5%F.S;

02 Sensor installation method: installed inline at each anchor plate, meeting the IP67 protection level, and realizing the function of the rigging's own measuring device;

03 Sensor calibration method: The rigging is calibrated before leaving the factory, and no calibration is required on site;

04 The collection equipment is installed on the sensor side and connected through wired cables. The collection equipment is wirelessly transmitted to the network management gateway, and the gateway transmits it to the cloud platform through the GPRS network for display, storage and query, and the data collection granularity can be set;

05 The system can automatically complete remote data transmission. The cloud platform center processes and analyzes the measured data, and can realize the function of sending detection data reports and over-value warning information to the client. It has strong compatibility, and the measurement end, collection end, and platform can all implement standardized data interfaces to facilitate customer data application or development.

The entire system is divided into perception layer, collection and transmission layer, cloud processing layer and application layer. The sensing layer installs sensors through welding to realize real-time monitoring of the load stress of the rigging. The acquisition device collects signals and transmits them to the cloud platform through the ZIGBEE/GPRS wireless network. The cloud platform center processes and analyzes the uploaded data. Finally, Test results, data reports, and early warning confidence are sent to the client.

Software Application

The software application is mainly based on the rigging requirements, briefly sorting out the framework and function points of existing localized products, cloud platforms, and considering the support for the rigging detection system. The system can provide a good human-computer interaction interface to facilitate user operation and has the following functions:

Perception System

Smart Cable

Cables are widely used in large structures such as large bridges and have very important social significance and economic value to the bridge operation department. Intelligent cables will generally adopt institutional health detection technology that installs the detection system on the bridge after the bridge is completed, leaping to the point where the detection system and the structural system are truly organically integrated.

Working Principle

The intelligent cable system consists of intelligent induction nuts, cable bodies and other cable components, collection and transmission equipment, cloud and application terminals. When the cable is stressed, strain can be induced on the cable nut and cable body, and the acquisition equipment can collect the data at the sensing end and transmit it to the cloud through wired or wireless transmission, so that the detection data can be directly viewed or processed.

Intelligent Cable Force Measurement Process

① Intelligent cable production → ② Intelligent cable calibration → ③ On-site installation and layout of cable and equipment → ④ Load monitoring, of which ① and ② are completed in the factory, and ③ and ④ are implemented at the construction site. The development of smart cables can realize the load detection of the cable during tensioning and long-term load monitoring after anchoring, and at the same time realize portable installation, which can meet the construction requirements of current structures.

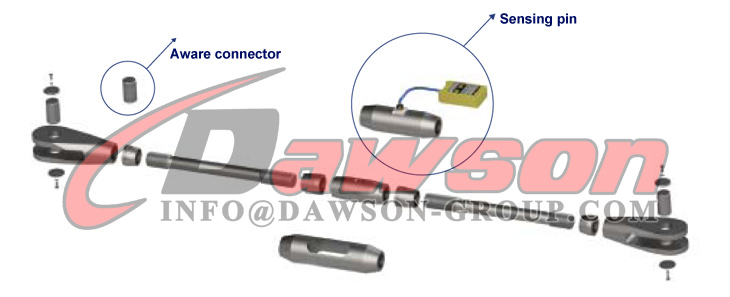

Smart Steel Tie Rod

Steel tie rods have the advantages of high strength, good toughness, economy and applicability, and have been widely used as direct units in prestressed steel structures. Whether the prestressed steel tie rods meet the design requirements during construction will be directly related to the load-bearing capacity and safety performance of the prestressed structure. Therefore, the detection and monitoring of its internal forces have become an important part of the construction stage. At present, the force measurement methods of steel tie rods mostly use the torque coefficient method or the hydraulic conversion method. The measurement results are affected by many factors, and the comprehensive factors are relatively large. It is difficult to meet the current construction requirements of prestressed steel structures. Smart steel tie rods are designed to realize the sensing and monitoring of structures through a set of smart steel tie rod systems. Provide effective evaluation data for construction personnel, construction and operation units, and colleagues on site Achieve convenient, fast, safe and effective installation.

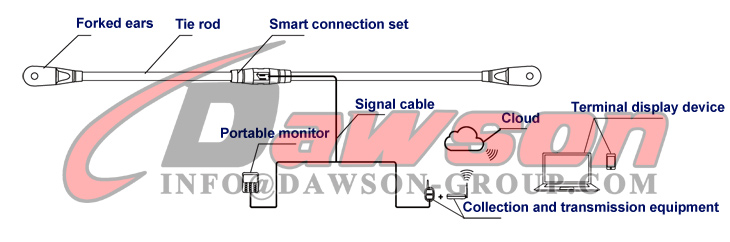

Working Principle

The smart steel tie rod system consists of steel tie rod components such as induction fork lug pins or smart connections, collection and transmission equipment, cloud, and application terminals. The sensing principle adopts principles such as vibrating wire and resistance. When the steel tie rod is stressed, it can be sensed on the fork lug pin or connecting sleeve. The data of the sensing section is collected through the acquisition and transmission equipment and transmitted to the cloud through wired or wireless transmission. On the application side, you can directly check the stress status of the steel tie rod or process the detection data.

Smart Steel Tie Rod Force Measurement Process

① Production and production of smart steel tie rods → ② Calibration of smart steel tie rods → ③ On-site installation and layout of steel tie rods and equipment → ④ Load monitoring, of which ① and ② are processed in the factory, and ③ and ④ are implemented at the construction site.

The development of smart steel tie rods can realize load detection of steel tie rods during tensioning and long-term load monitoring after installation, while also achieving portable installation, which can meet the construction requirements of current structures.

Fork lugs, tie rods, smart connection sleeves

Portable display signal cable cloud terminal display equipment

Collection and transmission equipment

Advantage comparison

1High compatibility

Intelligent rigging itself is a system that can be connected to other subsystems as a main system or integrated into other systems as a subsystem. It has high compatibility; traditional sensors have poor compatibility and are incompatible with many systems and have great limitations.

2 System implementation efficiency

The system can be quickly brought online without complicated wiring.

3 On-site installation efficiency

Intelligent sensors, cables and rigging adopt integrated equipment or installation, which does not affect the normal installation and use of rigging, and the system adopts a wireless distributed design. Traditional sensors require on-site technical guidance from professionals for installation, and no wiring is required on-site, reducing on-site implementation and maintenance costs.

Engineering Project Cases Catalogue Download:

Package and Factory Show:

English

English